Millson Engineering have been carrying out die refurbishment for over 40 years and have been at the forefront of developing the procedures required. Our refurbishment starts with a visual inspection of the die to ensure there is no substantial damage present.

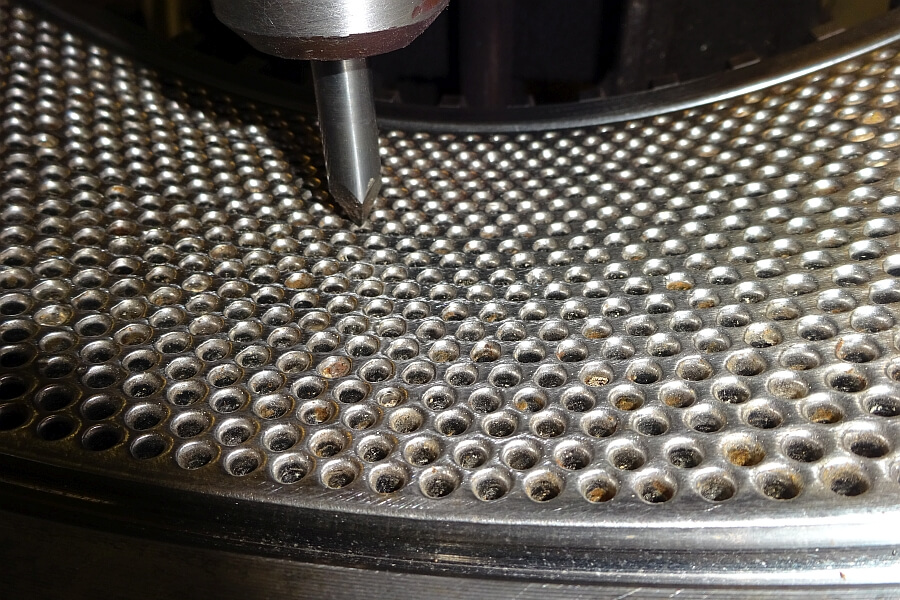

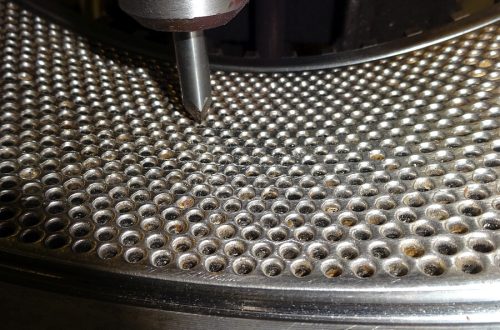

The die is cleared of all product and cleaned and the track is machined and all holes are re countersunk. The die is again cleaned and inspected prior to wrapping and despatching with a collection and delivery service available.